The White Claw Vending Machine

ROBOTICS EXPLORATION

Design and build a household-size white claw vending machine that fits the college party scenario with Venmo payment and a modern aesthetic.

MY ROLE

Industrial Designer

TEAM

Cross-functional team of 6.

Include Brown University Computer Science and Electrical Engineering Undergrads and myself as the Solo Designer.

TOOL

Fusion 360, 3D printing, Laser cutting, Arduino, Raspberry Pi, woodworking, metalworking

DURATION

1.5 Months.

Initial Design Iteration

Dropping the can vertically would require very precise timing and might be too difficult to code.

_PNG.png)

_PNG.png)

Looks too much like a standard vending machine.

_PNG.png)

_PNG.png)

Starting to play with shape to create unique modern looks.

.png)

.png)

Final Design Sketch and User Flow

Rapid Prototyping

While I work on refining the 3D model in Fusion 360, we have to constantly build rapid prototype to allow my computer science teammates to test out their code, and at the same time be able to test out each component hardware design.

Testing out can dispenser form and gears.

_PNG.png)

_PNG.png)

Testing out receipt printer.

_PNG.png)

Testing out one magazine with scrap materials.

_PNG.png)

Troubleshooting highlight

V2: After talking to TA, we realized that it would be good to have extruding parts for bearings to sit on, and we also need an edge/extruding part if we want to use a limit switch.

V1: too long, white claw rocking too much inside, some holes should be through holes.

V3: Extruded parts for bearings to sit on. One edge of the can dispenser is taller than the other for use of limit switch. Edges are rounded for better 3D printing quality and smoother can dispensing motion.

Can Dispenser 3D Printed Prototype Refining:

Reducing Laser Cutting Time:

We learned that instead of using the rastering technique of the regular engrave black shape, switching it to closely place together blue scoring lines can significantly reduce the laser cutting time.

2 hours to complete the cut.

_HEIC.png)

17 minutes to complete the cut.

_HEIC.png)

Finding the Optimal Funnel Slope Angel:

Our goal was to find an optimal angle for the can to slide down smoothly and be able to stand straight when dispensing to the opening. Besides playing around with the angel we also change the slope material from wood to smooth metal sheet.

.png)

Designing Receipt Printer Door:

Since the receipt printer we ordered did not include the case, we had to design a way to attach the printer onto the vending machine ourselves.

Referencing from existing printer case

Our redesign

.jpg)

Final Fusion 360 CAD Model

Assembling Process

_PNG.png)

_PNG.png)

_PNG.png)

_PNG.png)

_PNG.png)

Video Final Demo

Detail Annotation

.png)

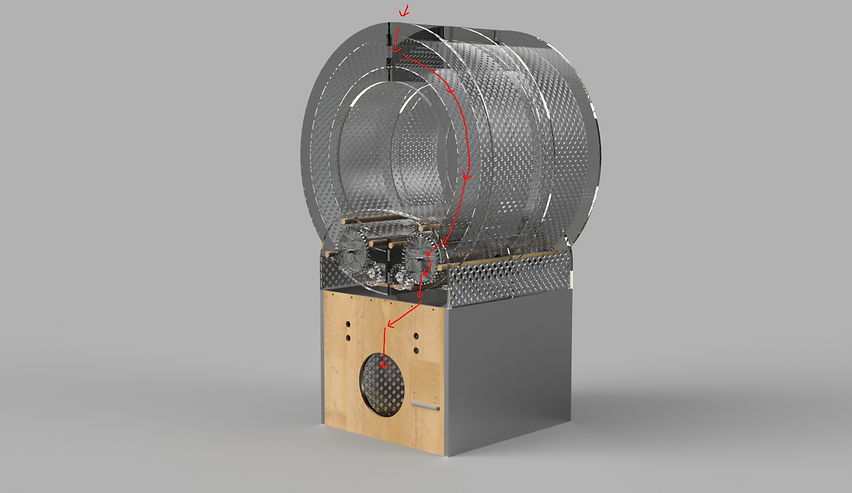

How a White Claw travel through the machine

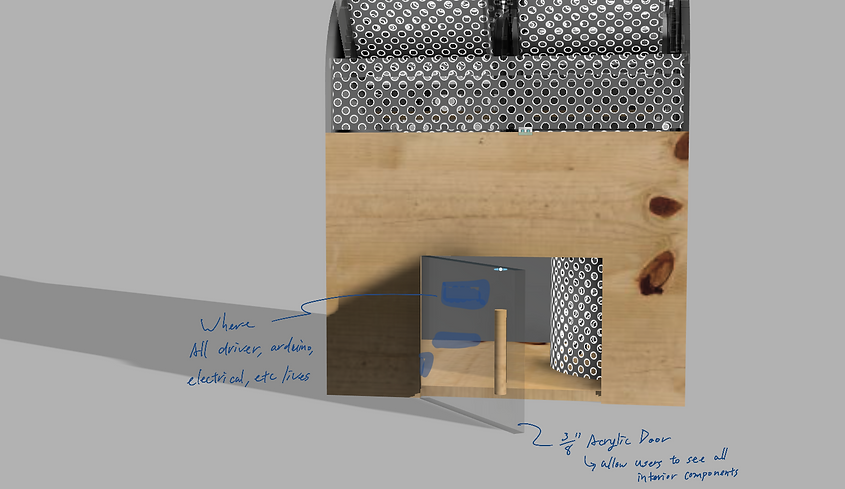

Major Components

Major Components

.png)

Magazine Structure

.png)

Base Structure

Side Door

Long wooden dowels that hold together the four magazines to the base structure

Takeaways

Besides learning about the design of hardware and mechanism, I learned about the importance of keeping constant communication within an interdisciplinary team, and the importance of dividing the hardware design into multiple testable components so the electrical and software team can test out their parts.

One of the most fun parts was learning about unfamiliar fields from each other. For example, I learned about the basic flow of Raspberry Pi to Arduino, the importance of wire management, and how to play with different voltages when having multiple components. On the other hand, I taught others the basics of drilling holes, laser cutting, and metal cutting.